DeepMould.net: Leading Metal Fabricators Providing Exceptional cnc machining parts service

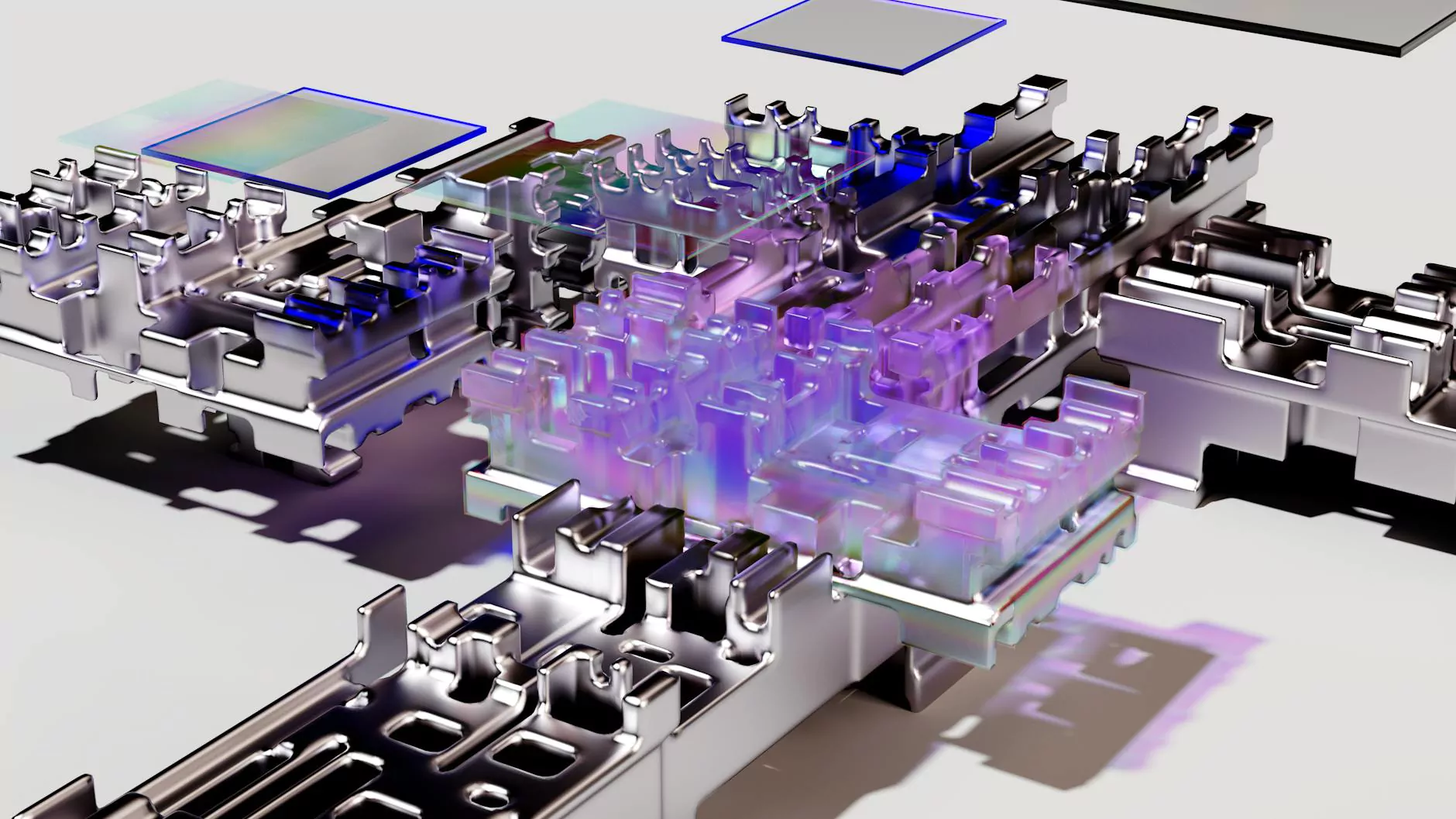

In the competitive arena of metal fabrication, delivering high-quality, precise, and reliable manufacturing solutions is essential for maintaining a competitive edge. DeepMould.net has established itself as a prestigious leader in the industry, specializing in serving a diverse range of sectors including aerospace, automotive, electronics, medical devices, and industrial machinery. Our core strength lies in our comprehensive cnc machining parts service, which combines cutting-edge technology with exceptional craftsmanship to meet the most demanding specifications.

Why Choose DeepMould.net for Your cnc machining parts service?

- State-of-the-art Technology: Equipped with the latest CNC machinery, we ensure unparalleled precision and efficiency.

- Experienced Engineering Team: Our professionals possess comprehensive knowledge of metal fabrication processes, ensuring optimal design for manufacturability.

- Comprehensive Material Selection: From Aluminum and Copper to Steel and Titanium, we offer a broad range of materials tailored to your project requirements.

- Strict Quality Control: Rigorous inspection protocols guarantee that every component meets international standards and your specifications.

- Fast Turnaround & Competitive Pricing: Leveraging advanced automation and optimized workflows, we deliver quality products promptly and affordably.

Innovative Metal Fabrication Solutions Powered by Advanced Technology

DeepMould.net’s commitment to innovation is reflected in our adoption of modern manufacturing technologies. Our cnc machining parts service integrates various methodologies, including CNC milling, turning, drilling, and precision grinding, to produce highly intricate and precise components. We leverage CAM (Computer-Aided Manufacturing) software to develop detailed tooling strategies, ensuring every part adheres to tight tolerances and complex geometries.

Such technological prowess allows us to manufacture components with extreme accuracy, ensuring they fit seamlessly into your assembly line or product design. Our machinery supports a vast array of sizes and complexities, from micro-scale parts to large, heavy-duty components. Whether you require simple prototypes or high-volume production runs, our facility is equipped to handle it all.

Our End-to-End cnc machining parts service Process

We believe that a transparent and streamlined process translates into superior results and satisfied clients. Here’s how our cnc machining parts service works:

- Design Consultation & Prototype Development: Collaborate with our engineering team to optimize your design for manufacturability. We provide design for manufacturability (DFM) feedback and prototype creation for initial testing.

- Material Selection &Quotation: Based on your application, we recommend the most suitable materials and provide a detailed quote ensuring cost-effectiveness.

- Programming & Setup: Our engineers meticulously program the CNC machines, ensuring the highest precision and adherence to specifications.

- Production & Quality Assurance: Manufacturing is carried out with continuous monitoring and inspection. Advanced measurement tools such as CMM (Coordinate Measuring Machines) are used for quality verification.

- Final Inspection & Delivery: Every piece undergoes thorough inspection to meet strict standards before being packaged and shipped securely.

Comprehensive Material Capabilities for Diverse Industry Needs

One of the hallmarks of our cnc machining parts service is our extensive material expertise. We cater to industries requiring different properties, including strength, corrosion resistance, thermal stability, and lightweight characteristics. Our material portfolio includes:

- Aluminum Alloys: Ideal for lightweight structural components, aerospace parts, and electronic housings.

- Stainless Steel: Suitable for medical instruments, food processing equipment, and corrosion-resistant applications.

- Copper and Brass: Used in electrical connectors, plumbing components, and decorative parts.

- Titanium: Perfect for high-performance aerospace and medical applications requiring high strength-to-weight ratios.

- Specialty Alloys: Including Inconel, Hastelloy, and others for extreme environments demanding resistance to heat, corrosion, or wear.

Unmatched Quality Assurance & Certifications in Metal Fabrication

Quality is the foundation of our reputation. DeepMould.net adheres to strict quality assurance protocols, including ISO 9001 certification, to guarantee the reliability and consistency of every product. Our quality control process encompasses:

- Regular calibration of equipment to maintain measurement accuracy

- Strict adherence to customer specifications and tolerances

- Use of high-precision inspection tools such as CMMs

- Documentation and traceability of all production runs

- Continuous staff training to uphold the highest standards in manufacturing and safety

Efficiency, Sustainability, and Customer Satisfaction

Beyond manufacturing excellence, our commitment extends to environmentally sustainable practices, waste reduction, and energy-efficient operations. We prioritize:

- Utilizing eco-friendly materials and recycling scrap metal

- Implementing lean manufacturing principles to maximize efficiency

- Providing exceptional customer support to address unique project challenges

- Offering flexible order quantities to accommodate startups to large corporations

Industries That Benefit from Our cnc machining parts service

Our extensive experience allows us to serve various industries that demand precision metal components:

- Aerospace: Ensuring component reliability under extreme conditions

- Automotive: Manufacturing durable, high-precision parts for vehicles

- Electronics: Producing delicate and miniature parts with tight tolerances

- Medical Devices: Creating biocompatible, sterile-grade components

- Industrial Machinery: Providing robust parts necessary for heavy-duty applications

Choose DeepMould.net for Your Metal Fabrication & cnc machining parts service

Partnering with DeepMould.net means collaborating with a trusted, innovative, and dedicated manufacturer committed to excellence, precision, and customer satisfaction. We strive not only to meet but to exceed your expectations through continuous improvement, technological innovation, and personalized service.

Contact Us for Your Custom Metal Fabrication Needs

If you are seeking a reliable provider of cnc machining parts service, DeepMould.net is your optimal choice. Our team is ready to assist you at every stage of your project, from design and prototyping to production and delivery. Reach out today to discover how we can add value to your manufacturing process and help accelerate your project timelines with quality-assured solutions.